We will be a global service provider of EMS electronic manufacturing services.

Our services include 1-36 layers of fine PCB manufacturing, FPC flexible circuit board production, full BOM component sourcing, SMT placement, post-soldering insertion and project testing and assembly, triple-proof paint coating, etc.

Our Services

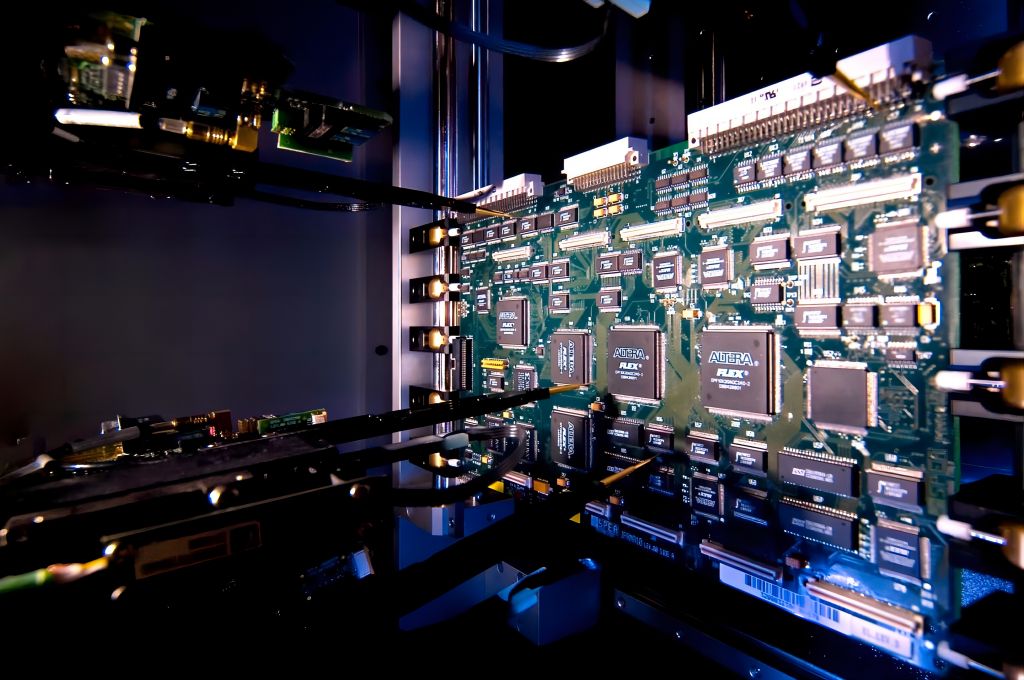

PCB/FPC

Supports complex processes such as 1 to 36 layer multilayers, HDI, blind buried vias, BGA, hole-in-disk, gold fingers, resin plug holes, laser drilled holes, 3 mil line width line spacing, and more.

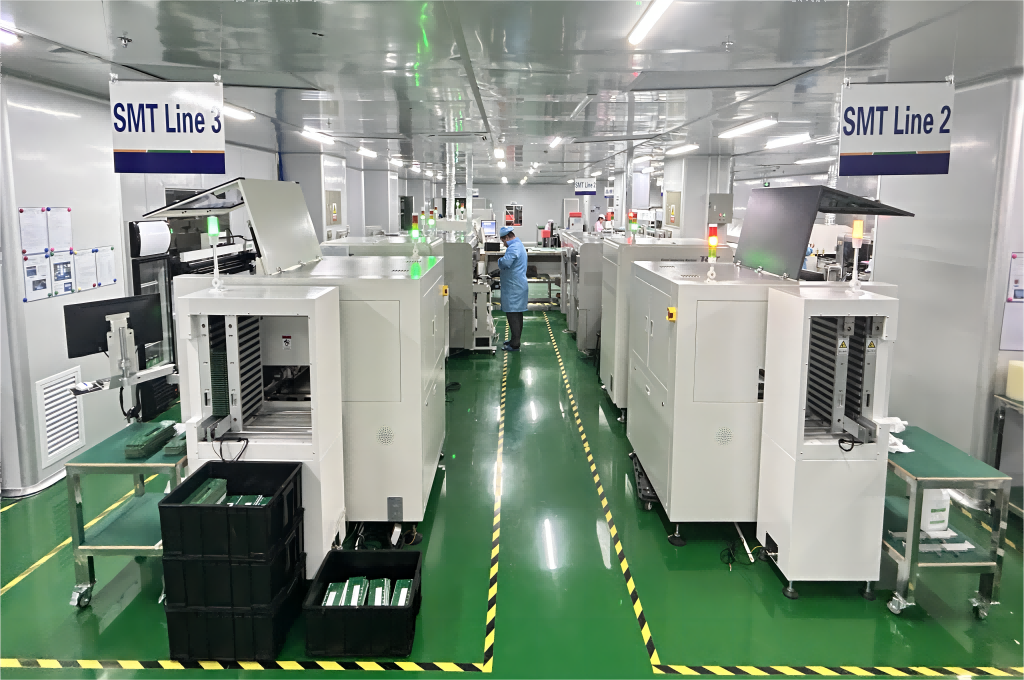

PCBA

We can provide one-stop PCBA services such as 0201/BGA/CCGA Surface Mount (SMT), Through Hole (THT), Mixed Technology (SMT and Through Hole), Conformal Coating, Pouring and Encapsulation, AOI/X-RAY PCBA Testing and so on.

Test

A variety of test services are available including visual inspection, in-circuit test (ICT), flying probe test (FPT), functional circuit test (FCT), and boundary-scan (JTAG).

Our process capabilities for DIP insert processing

Plug-in AOI for component error leakage reverse detection, strict control of DIP through rate, receive strict training of skilled soldering iron hand, soldering speed and quality can be controlled, strict IPQC and QA LOT sampling standards, to ensure the reliability of DIP processing.

(e.g., automatic depaneling machines, automatic dispensers, automatic spot welders, etc.), tooling fixtures, etc., make our DIP processing services highly consistent and reliable.

Delivering value and creating capacity

Company Profile

HENTECH INDUSTRIAL CO., LIMITED. is committed to providing customers with PCB production, component purchasing, SMT, DIP, assembly and testing of PCBA one-stop service.

Getting Recognized

We have passed the system certifications of ISO9001, ISO14001, ISO13485, IATF16949, etc., and strive for quality.

Enterprise development

We have established a flexible production system for samples, small and medium-sized batches, and multiple batches, with the advantageous features of quick quotation, quick production and quick delivery.

PCB&PCBA Production

Our services are available worldwide

Start your offerings customization journey

HENTECH INDUSTRIAL CO., LIMITED

Contact Us

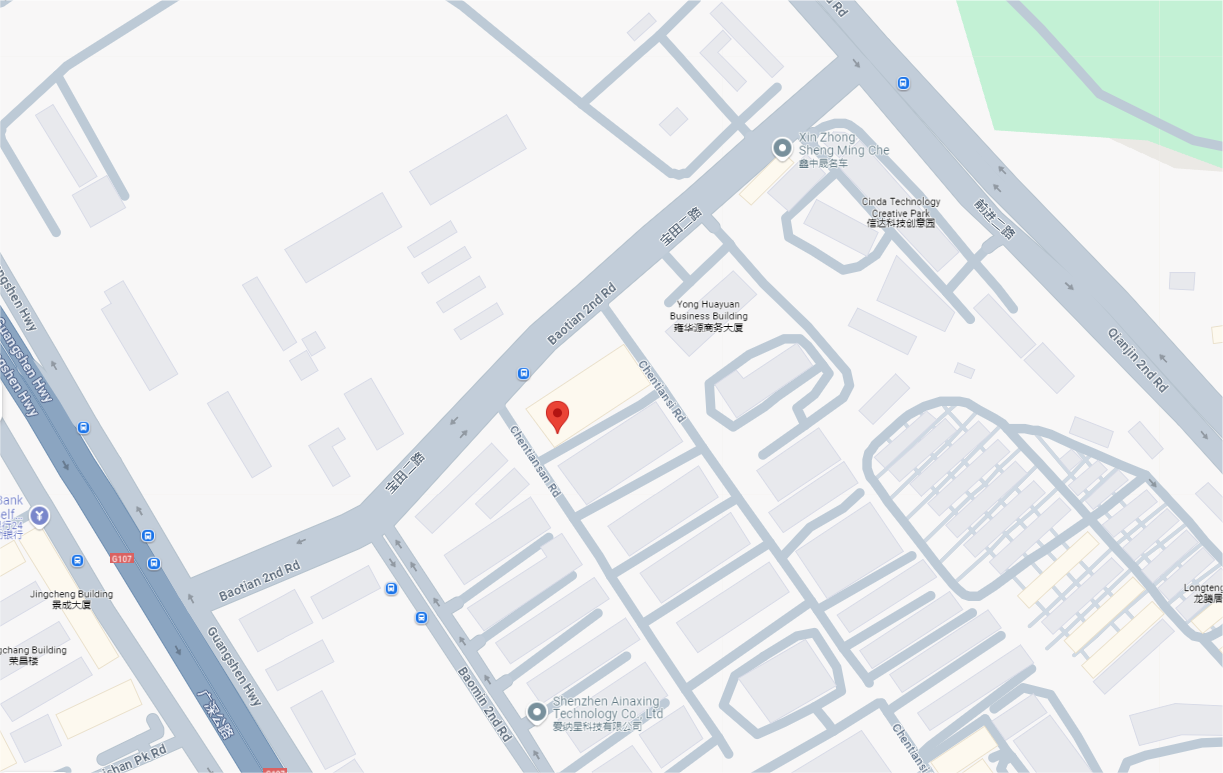

Address : Room A, 3/F, Block 28, Chentian Industrial Area, Baotian 2nd Road, Xixiang Town, Bao’an District, Shenzhen, China

Tel : 0755-2998 5486

WhatsApp : +852 69181721

Email : sales@hengele.com