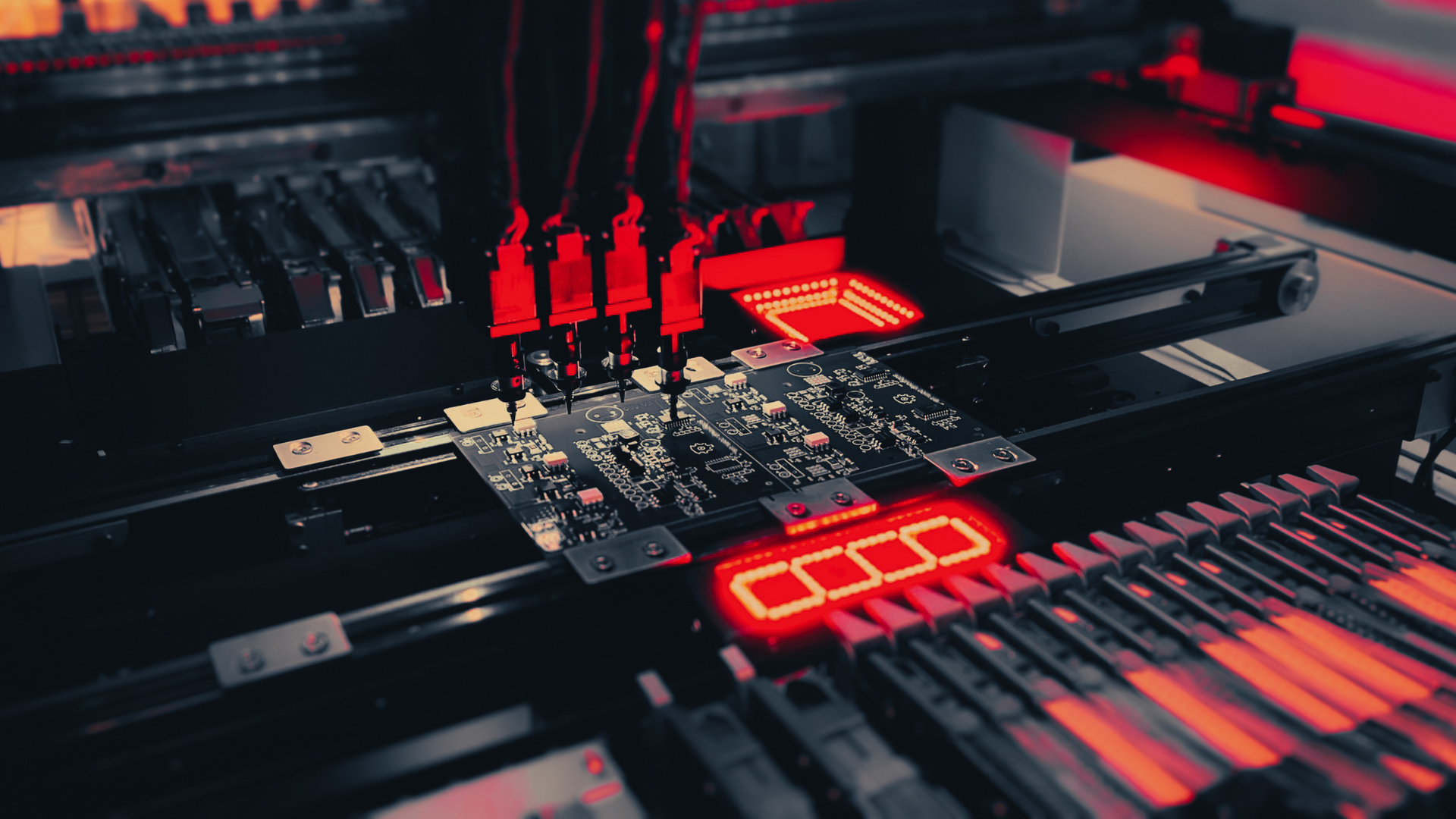

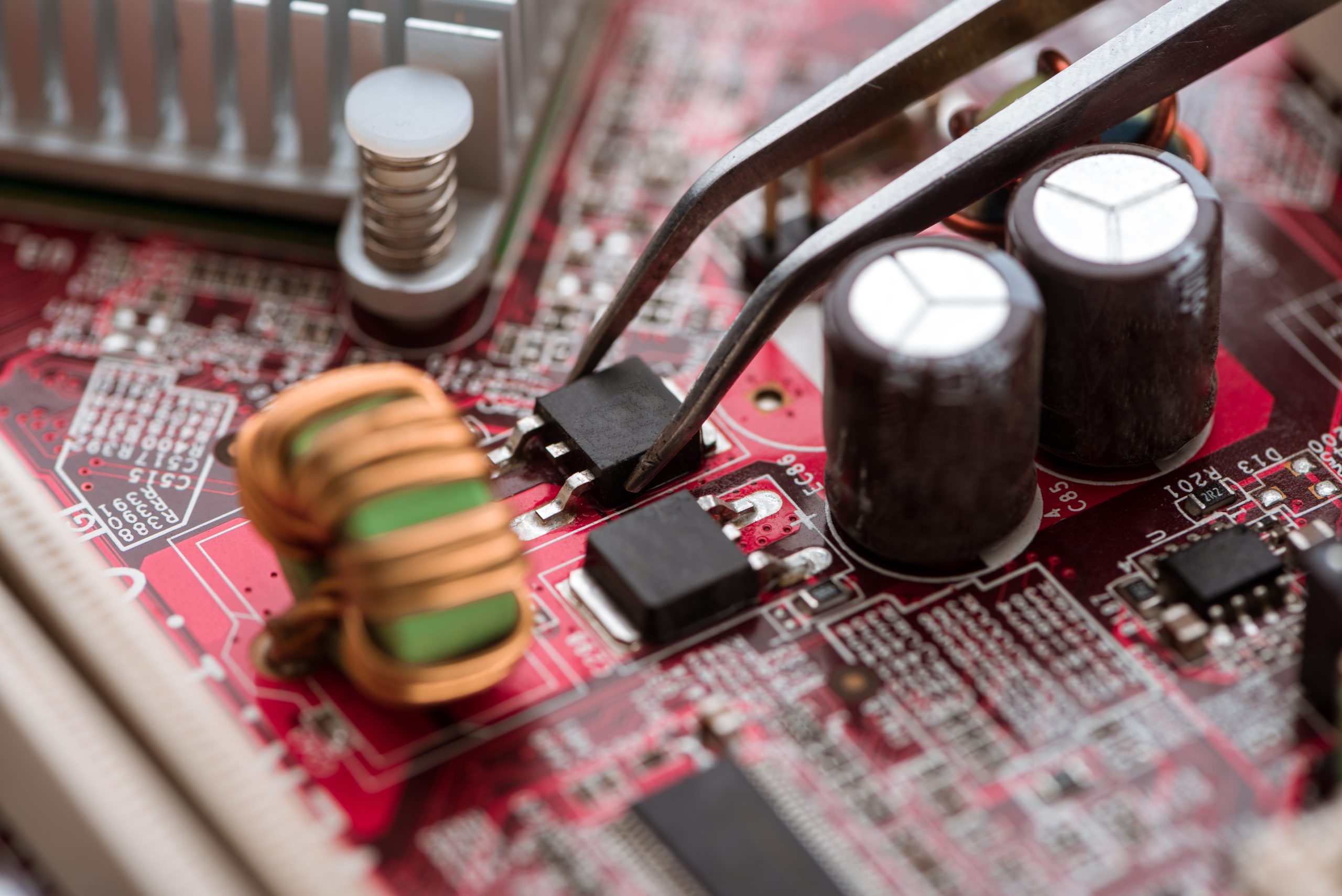

Surface Mount Technology (SMT)

Surface Mount Technology (SMT) production and screen printing are core components of our PCB assembly services. Our factory is equipped with multiple advanced pick-and-place devices, enabling us to manufacture a diverse range of circuit board assembly products that comply with the IPC-A-610 standard.

Test/Inspection

All components are inspected manually and automatically using high-magnification optical inspection (AOI) to detect component-level and pin-level defects, such as missing components, polarity errors, or insufficient solder joints. We also offer more comprehensive in-circuit testing (ICT) to ensure product quality and meet multiple regulatory requirements. Our services can be flexibly customized to help you create testing and inspection solutions that meet your specific needs.

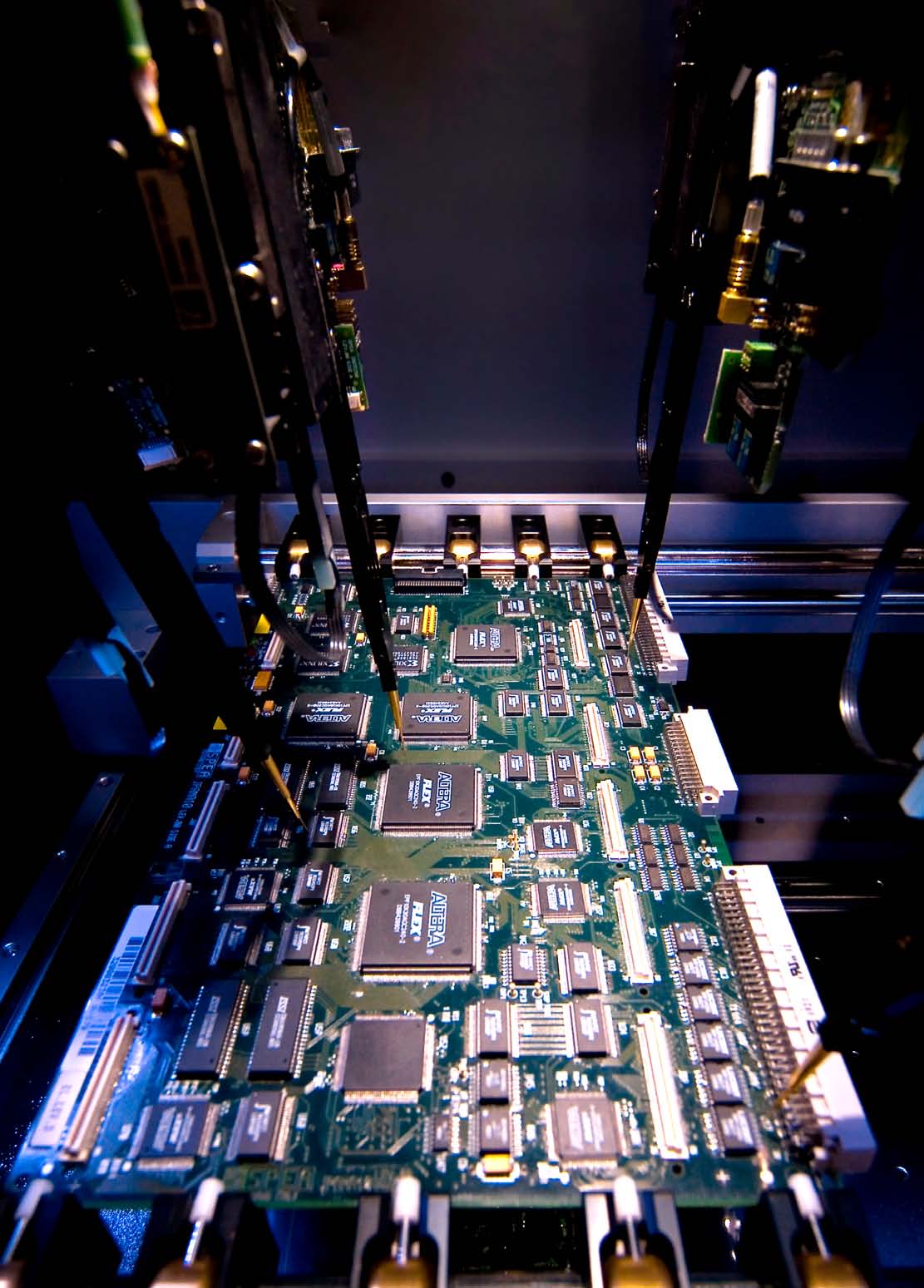

PCB Parts Sourcing

The current market supply of printed circuit board (PCB) components is relatively tight, and as demand continues to grow, it is becoming increasingly difficult to procure components independently. Choosing to work with PCB and integrated circuit suppliers that offer high-quality components can optimise your procurement process and help you meet your business needs.

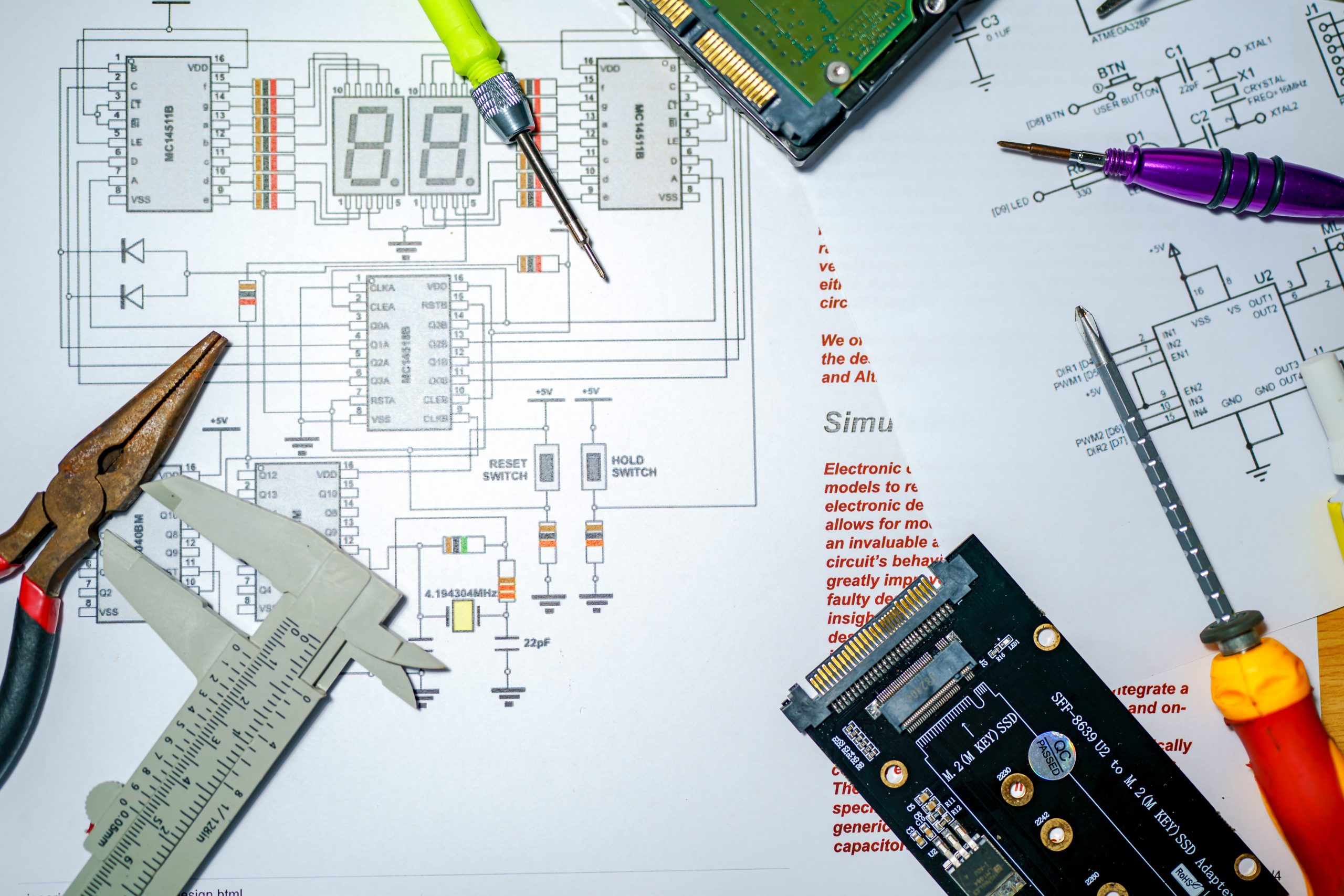

PCB Design Services

With extensive expertise in PCB design, our team of PCB engineers and designers, decades of experience, and over 1,000 PCB assembly designs, we are fully capable of meeting your requirements.

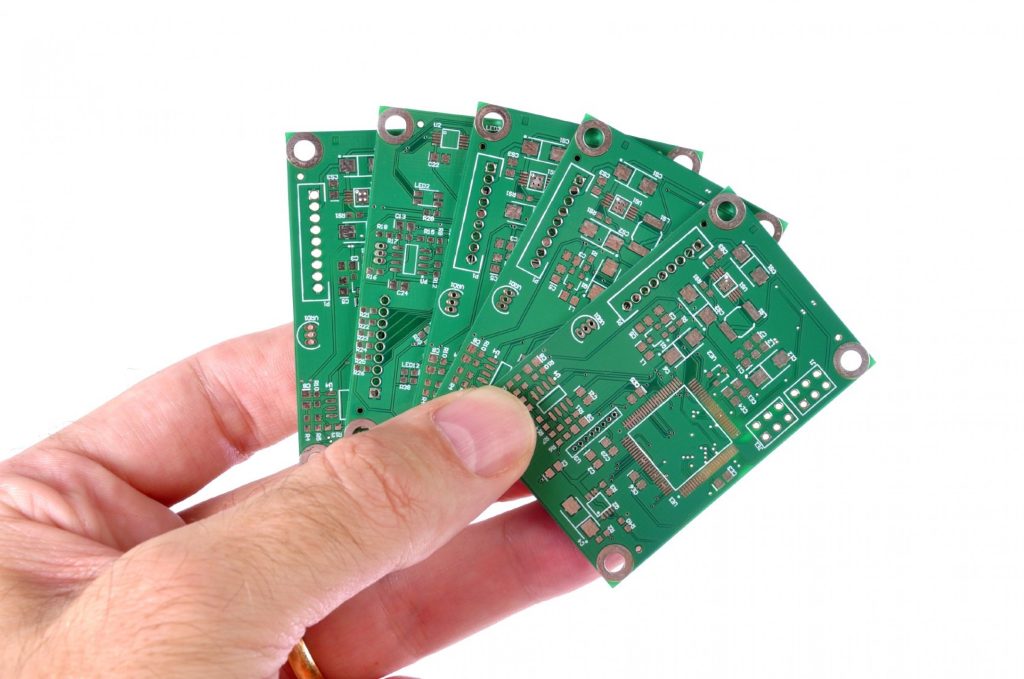

PCB Assembly

We continue to strengthen our technical capabilities and production capacity, and have become a leader in the high-end PCB assembly service industry. As a company specialising in electrical assembly, we excel at producing small batch orders of less than 50,000 pieces and provide comprehensive inspection, testing and quality control services to help you develop finished products and prototypes that meet your needs.

PCB Assembly Process

Choosing a reliable PCB manufacturer is critical to ensuring timely delivery and excellent performance of electronic products. A reputable manufacturer can help you reduce overall costs while optimising the entire assembly process, from the initial consultation stage and prototyping to final assembly and delivery.

Get In Touch

Contact Us Now

Hentech Industrial offers comprehensive design and manufacturing services with a focus on OEM solutions. We provide complete hardware solutions, from small-scale to large-scale manufacturing, integration, and testing services, ranging from simple to complex solutions, ensuring our manufactured products remain competitive regardless of quantity or procurement strategy. We serve clients in the aerospace, telecommunications, and industrial markets by reducing time and optimising costs through the elimination of multiple layers of vendor markups across the entire value chain.

Contact

Iphone:13798219394 Hentech Industrial Co., Limited

Factory Address

Room A, 3/F, Block 28, Chentian Industrial Area, Baotian 2nd Road, Xixiang Town, Bao'an District, Shenzhen, China

Call Us

+86 0755 29985486

Email Address

Sales@hengele.com Liam@hengele.com

Follow Our Social Media

Please feel free to contact us and learn more about us

You can work with us at any stage of your product planning – from embedded system design to manufacturing services to complete OEM solutions.

Products:

Printed Circuit Boards PCB

PCB Prototyping Services

Flexible and Rigid-Flexible PCB

PCB Surface Assemblies (SMT)

Cable Assemblies and Harnesses

QR code labels

Telephone : +86 0755 29985486

Phone

+86 13798219394

Sales@hengele.com Liam@hengele.com

Address

Room A, 3/F, Block 28, Chentian Industrial Area, Baotian 2nd Road, Xixiang Town, Bao'an District, Shenzhen, China

Quick Links

Subscribe

Subscribe to our email newsletter to find out which products are worth making and/or designing.